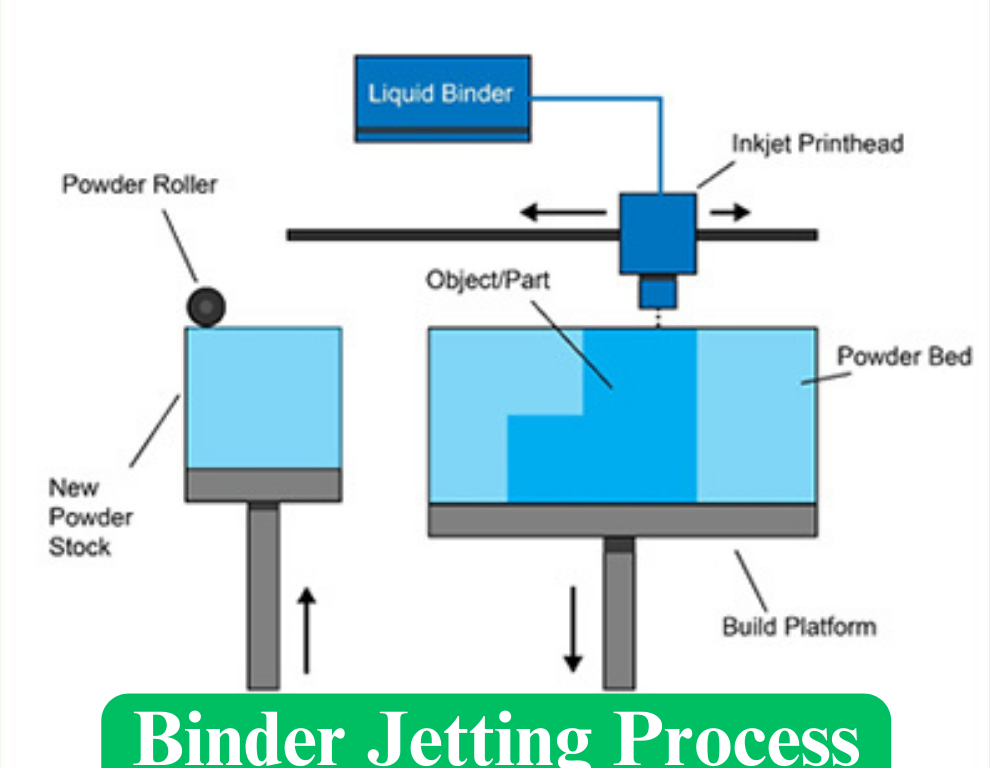

Binder Jetting is a type of 3D printing. The binder jetting procedure employs two materials: a powder and a binder. The binder works as glue between the powder layers. The binder is often liquid, while the construction material is powder. A print head rotates horizontally along the machine’s x and y axes, depositing alternating layers of construction material and binding material. The item being printed is lifted onto the building platform after each layer.

Binder Jetting – Step by Step

- A roller is used to disperse powder material across the building platform.

- The print head applies the binder glue to the powder as needed.

- The layer thickness of the model lowers the construction platform.

- Apply another coat of powder over the previous layer. Where the powder is joined to the liquid, the object is produced.

- The unbound powder remains in place around the item.

- The procedure is continued until the entire item is completed.

Technical information

- The binder jetting technique, which employs metal, polymers, and ceramic materials, enables color printing.

- The process is normally faster than others, and it may be accelerated even more by increasing the number of print head holes that deposit material.

- The two-material technique provides for a wide range of binder-powder combinations and mechanical characteristics of the final model by varying the ratio and individual qualities of the two components.

- As a result, the technique is ideally suited for when the interior material structure must be of a certain quality.

Materials

The following materials can be printed using the binder jetting technique:

- Metals: stainless steel, titanium, and aluminum are examples of metals.

- Ceramics: zirconia, alumina, and silicon carbide are examples of ceramics.

- Composites: Metal matrix composites and polymer matrix composites are examples of composites.

- Plastics: Nylon, acrylonitrile butadiene styrene (ABS), and polycarbonate are examples of plastics.

- Sand: utilized in foundry applications to make molds and cores.

- Glass: Binder jetting is being investigated as a potential approach for making glass objects.

Video Example of Binder Jetting

Advantages:

- Parts can be manufactured in a variety of colors.

- Makes use of a variety of materials, including metal, polymers, and ceramics.

- In general, the procedure is speedier than others.

- The two-material technique provides for a wide range of binder-powder combinations and mechanical characteristics.

Disadvantages:

- Because of the usage of binder material, it is not always suited for structural elements.

- Additional post-processing time can significantly lengthen the whole procedure.

You can read more articles on our blog

Pingback: What is 3D printing? - Sohaib Writes